High pressure steel wire braided hose

Classification:

Detailed

1. product structure:

The steel wire braided hose structure is composed of liquid-resistant synthetic rubber inner rubber layer, middle rubber layer, I or II or III layer steel wire braided reinforcement layer, and synthetic rubber outer rubber layer with excellent weather resistance.

2. product use:

Steel wire reinforced hydraulic rubber hose is mainly used in mine hydraulic support, oil field mining, it is suitable for transporting petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) liquid, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission with certain pressure and temperature in engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and mechanized and automated hydraulic systems of various industrial departments.

Note: The steel wire braided hose of this enterprise is designed and manufactured according to GB/T3683-1992 standard, and can be made according to the requirements of ISO/DIS1436-1985,DIN20022 and SAE100RIAT,SAE100R2AT standard hose. This standard is not suitable for castor oil base and fat base liquid.

3. working temperature: oil -40 ℃- 100 ℃, air -30 ℃- 50 ℃, water emulsion below 80 ℃, beyond please choose our special products

4. product features:

1. The hose is made of special synthetic rubber, which has excellent oil resistance, heat resistance and aging resistance.

2. The hose has high pressure and superior pulse performance.

3. The tube body is tightly combined, soft to use, and has little deformation under pressure.

4. The hose has excellent bending resistance and fatigue resistance.

5. The length of steel wire braided rubber hose is large, the fixed length above φ 32 is 20 meters, and the length below φ 25 can reach 10 meters or even more than 100 meters.

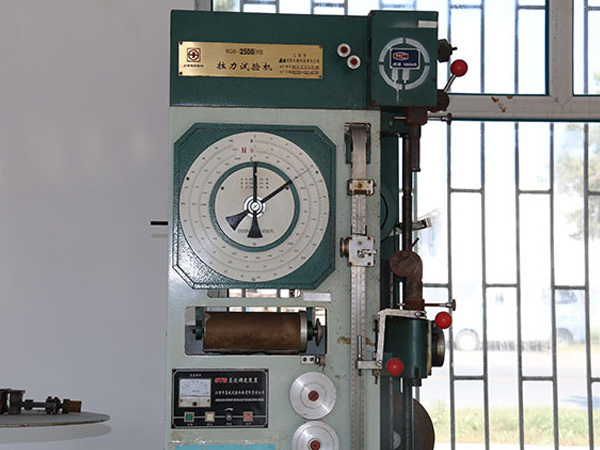

5. The high-pressure hose assembly produced by our company is made of high-quality steel wire braided hose or steel wire wound hose and hose joints, which are buckled by special equipment.

According to the needs of users can choose high-quality carbon steel joints, stainless steel joints, copper joints, aluminum joints, joint form and thread strictly refer to the national standard metric system

(JB1891-1900-77), American standards, imperial standards, etc., with accurate data, reasonable structure, convenient assembly, tight buckling, high temperature, high pressure and pulse

Under the working condition, it does not leak liquid, does not take off the head, has high safety factor and long service life, and can design and produce special-shaped joints and connectors according to user needs.

Note:

1. The bending radius should not be less than the given bending radius to prevent damage to the hose skeleton or early damage due to excessive extension.

2. According to the conditions of use, the correct selection of hose varieties, specifications, do not misuse or substitute.

3. When the hose is used, the pressure should be balanced and slowly adjusted to avoid sudden pressure increase and damage to the pipe body.

4. When the working place changes, it should be carried off the ground and not mopped to avoid scratching the outer rubber and corroding the skeleton layer.

5. Conveying corrosive liquid, the interior should be cleaned after use to prevent the residue from corroding the pipe body for a long time, or choose the corresponding series of products.

The above steel wire wound hose refers to GB/T3683-2011 standard. Please call for consultation if the specifications are not completed!

Key words:

High pressure steel wire braided hose

Previous Page:

Next page:

More Related Products

Online Inquiry

Fill in your phone number and E-mail information, and we will contact you as soon as possible.